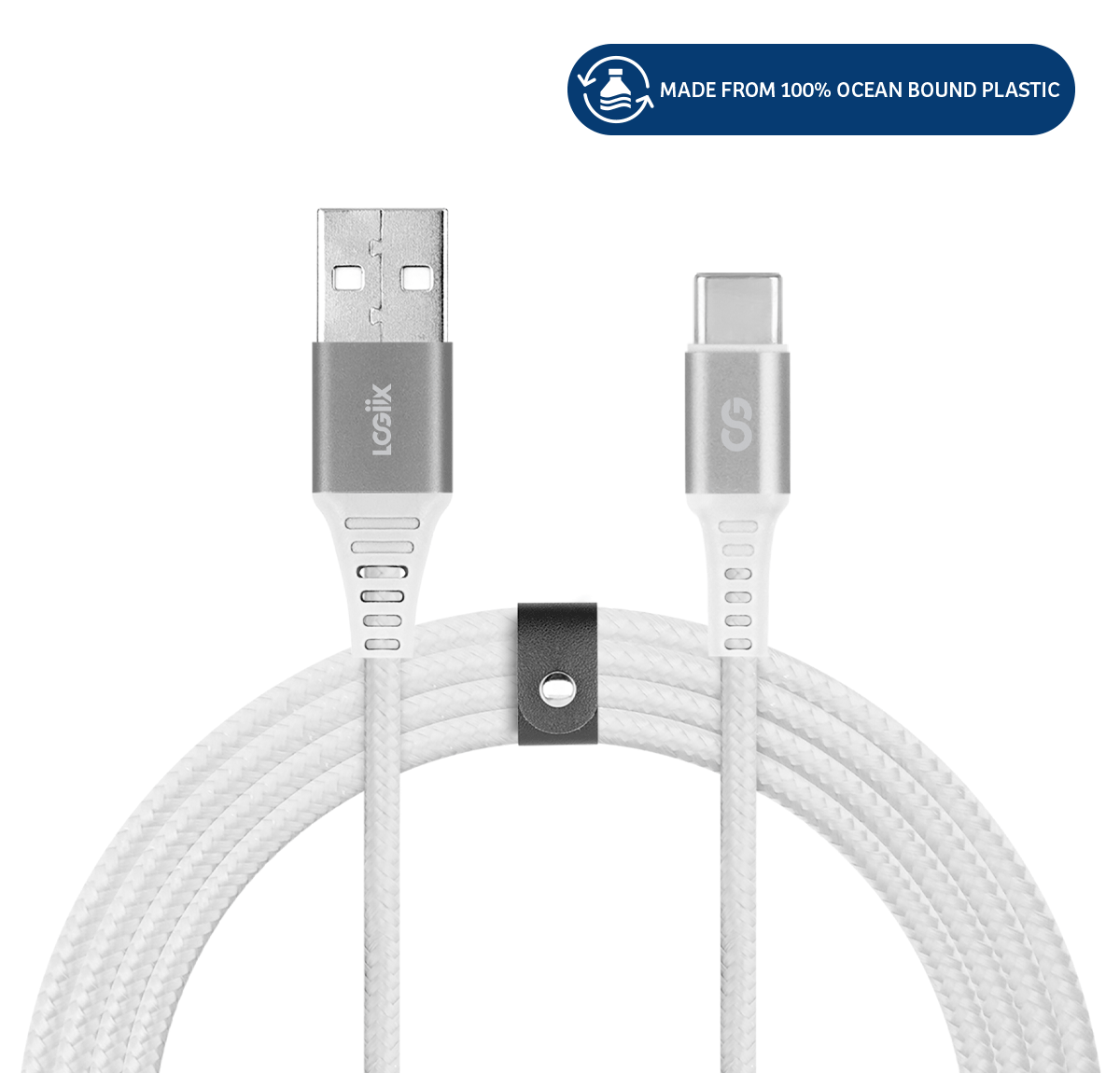

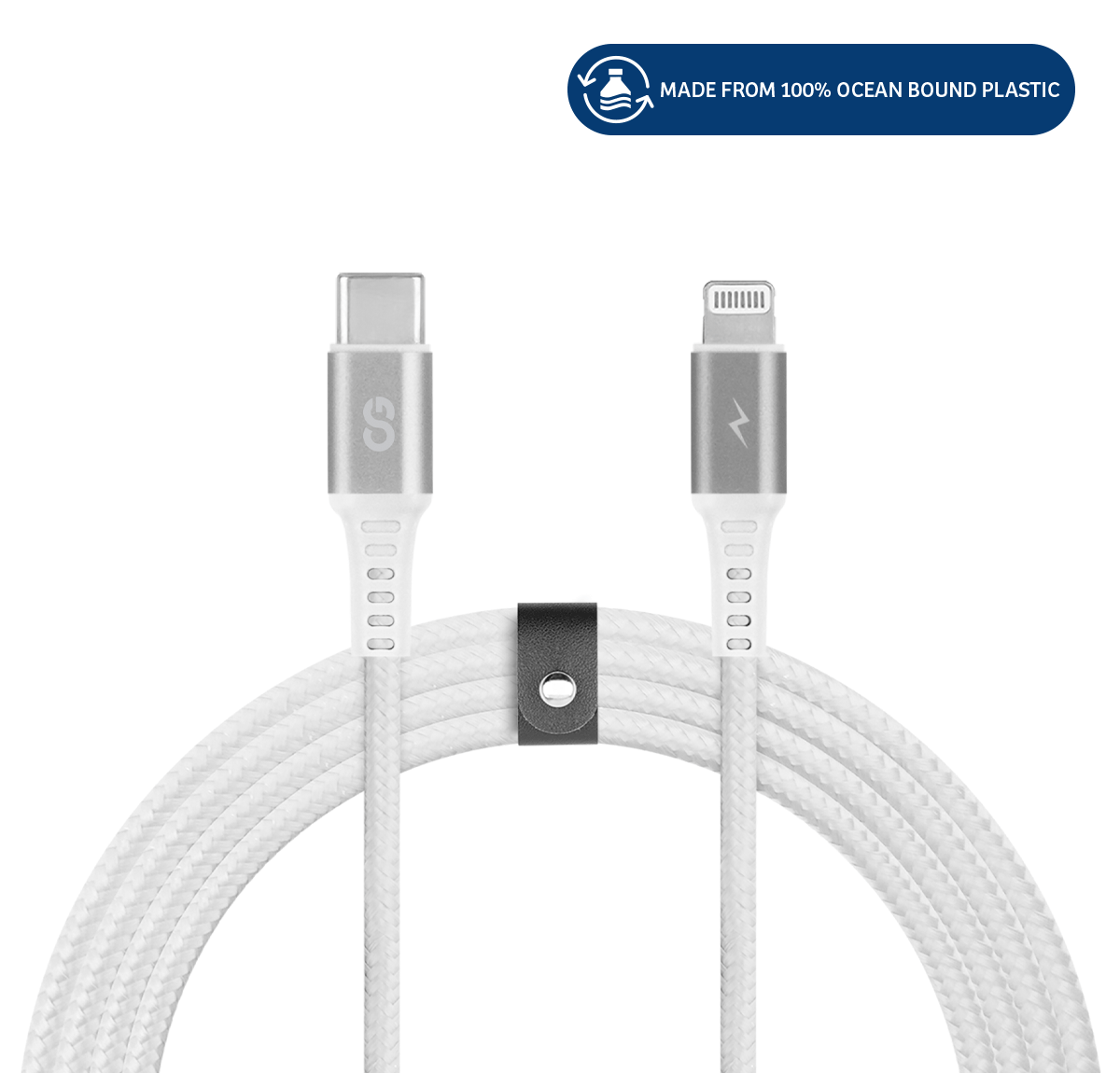

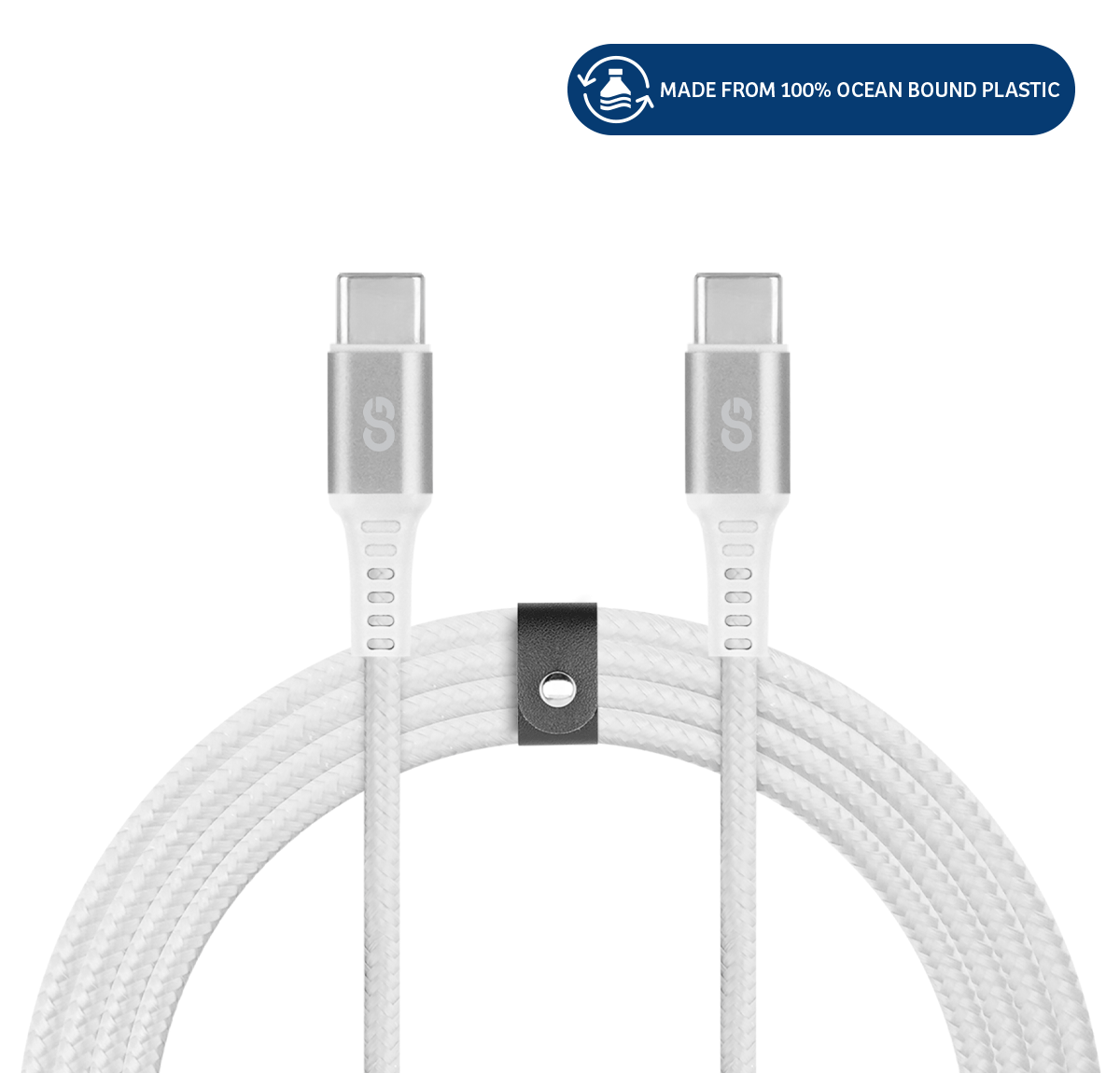

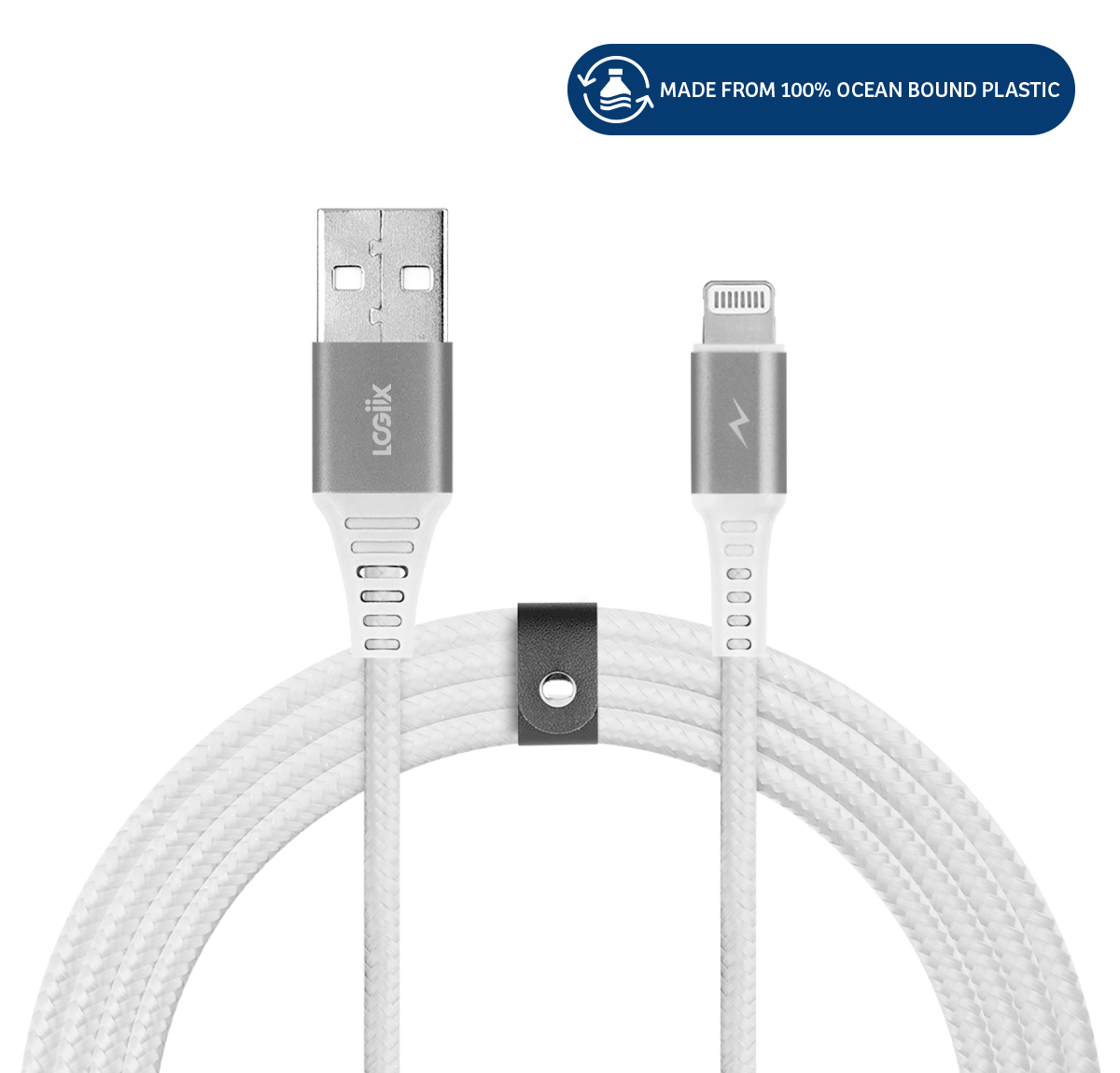

#tide® x LOGiiX

Here at LOGiiX, we have always worked towards ensuring that we are playing our part in creating a greener future. We have continued that effort and are proud to announce our partnership with tide ocean SA. #tide is a Swiss company, that works tirelessly to bring ocean-bound plastic collected on islands, beaches, along coastlines, and in uncontrolled landfills back to life. #tide transforms ocean-bound plastic into high-quality, award-winning materials for safe and durable products.

Developed in partnership with the Swiss University of Applied Sciences, #tide has created a science-based mechanical plastics recycling process to transform ocean-bound plastic waste into quality granules, yarns, and filament. The recycled plastic material is made of 100% ocean-bound plastic (OBP) and is OBP certified. Its high quality makes it an excellent replacement for virgin plastic. #tide®'s rPET pellets are five times more environmentally friendly than virgin PET.

Annually, more than 80% of the plastics polluting the oceans come from land-based sources.

Since 1950, close to half of all plastic has ended up in landfill or dumped in the wild, and only 9% of all plastic ever made has likely been recycled.

Step 1 | Collecting Plastic

The ocean-bound plastics are collected on islands, beaches, along coastlines and uncontrolled landfills. Exposed to sun, sea, sand and rain, the plastic waste is dirty, brittle and most importantly a threat to the environment. #tide pays fair wages to fishermen and local communities involved in the collection of ocean-bound plastics

STEP 2 | Sorting & Shredding

Collected material is sorted in Social Enterprises: For example, a plastic bottle is often made up of three different types of plastic: PET (bottle), PP (screw cap) and PET-G resins (label). The local teams ensure that these plastics are separated, cleaned and pressed into bales for further processing. We collect different types of plastics: PET, PP, HDPE or LDPE.

Step 3 | Controlling

The processing and recycling of ocean-bound plastic waste are overseen and monitored by #tide's Research and Development department, in collaboration with their partners at the Institute for Materials Technology and Plastics Processing (IWK), a specialized branch of Switzerland's University.

They ensure that the ocean-bound plastic material meets the quality standards set by #tide and recycle it using a mechanical process. The brittle ocean-bound plastic waste is transformed into premium recycled plastic pellets with an astounding purity level – without the addition of virgin plastics.

STEP 4 | Target Oriented Compounding

#tide's raw material is 100% recycled ocean-bound plastic. They recycle and upcycle ocean-bound plastic waste. Depending on the final product, #tide's experts know how to match the properties of the collected and recycled ocean-bound plastic waste to the manufacturing process. Each product has its own specifications - and #tide have the knowledge and network to make the impossible possible. They call it targeted compounding.

STEP 5 | Manufacturing

There's far too much single-use plastic ending up in landfills, rivers and ultimately the ocean: #tide's big goal is to change that by applying their recycled plastic pellets to all kinds of industries and products. #tide ocean material is a raw component ready for all kinds of plastic and textile applications. It can be processed into recycled plastic filaments, recycled polyester yarns and recycled fabrics (canvas). #tide's scientists and partners are constantly researching new applications and processes, from film extrusion to blow molding.

More on #tide?

Learn more about #tide, their efforts to transform ocean-bound plastics into sustainable materials and the amazing work they are doing to support local communities with employment & educational programs for the regions they work in!